April 27, 2016 Not all feet are created equal

Let’s just start off by saying feet are kinda weird, but they are so important to how we function as humans. Feet come in all shapes and sizes. We use our feet everyday as a mode of transportation and to support our weight. When designing a product for feet there are inherent challenges in creating a product that meets the vision of the designer and works for the variability of feet.

One solution is to design custom products for feet. Thankfully, the market for custom products has grown exponentially in the past few years, growing from artisanal craftsmanship to scalable digital processes. I’ve spent the last couple of years developing custom products for feet and it’s always challenging to figure out how to make a product custom. What information do you need from a foot to create a custom product? Is it arch height? Is it a footprint?

Usually the go-to answer is a set of measurements. While measurements are a great way to create custom products, there are many challenges in measuring feet. For anyone collecting hand measurements, precision and consistency are difficult to maintain. How to universally define key foot geometry (e.g., arch height or arch length) is still debated between biomechanics and anthropometrists. As a result, there needs to be a way to create a repeatable process that lets a designer iterate and scale changes.

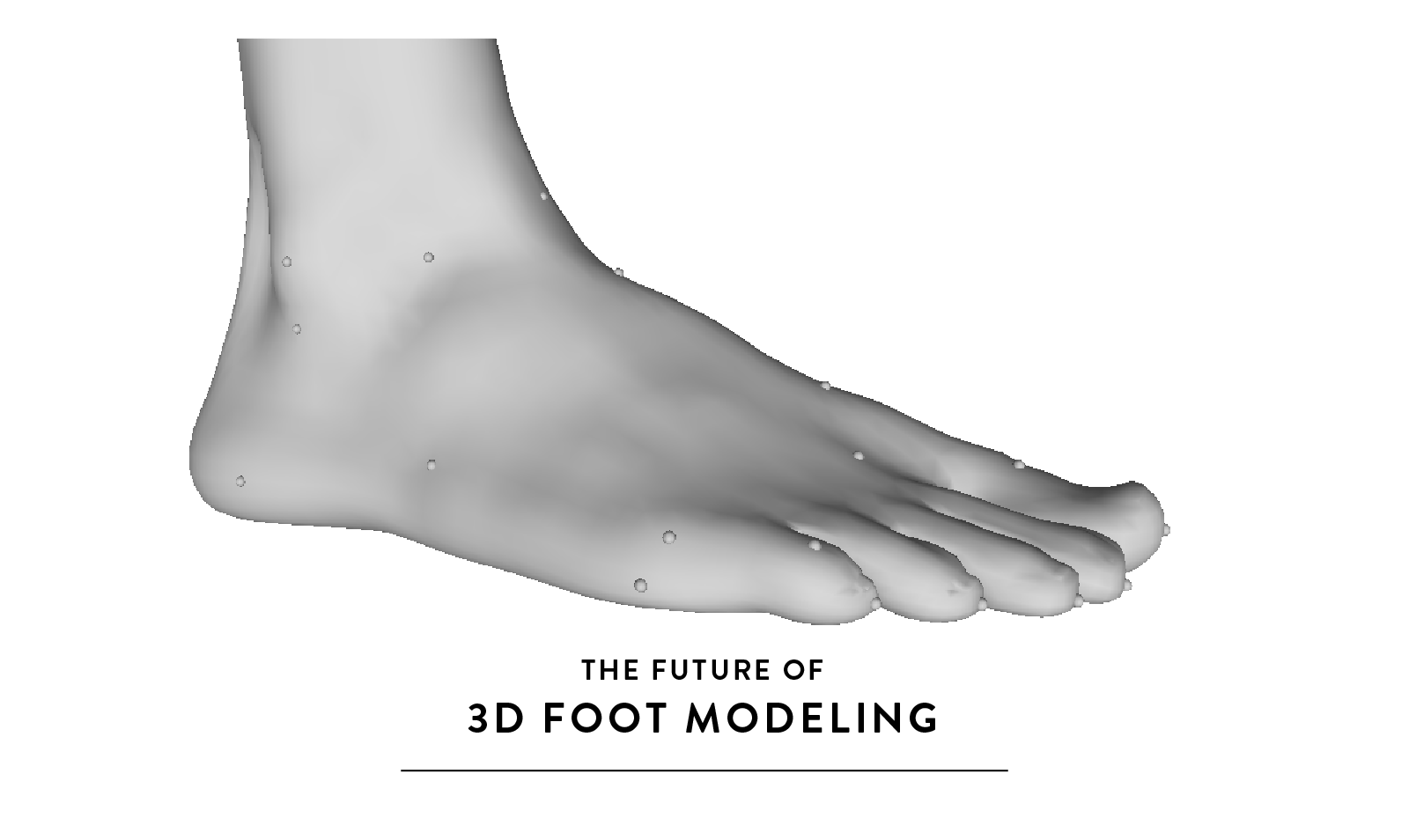

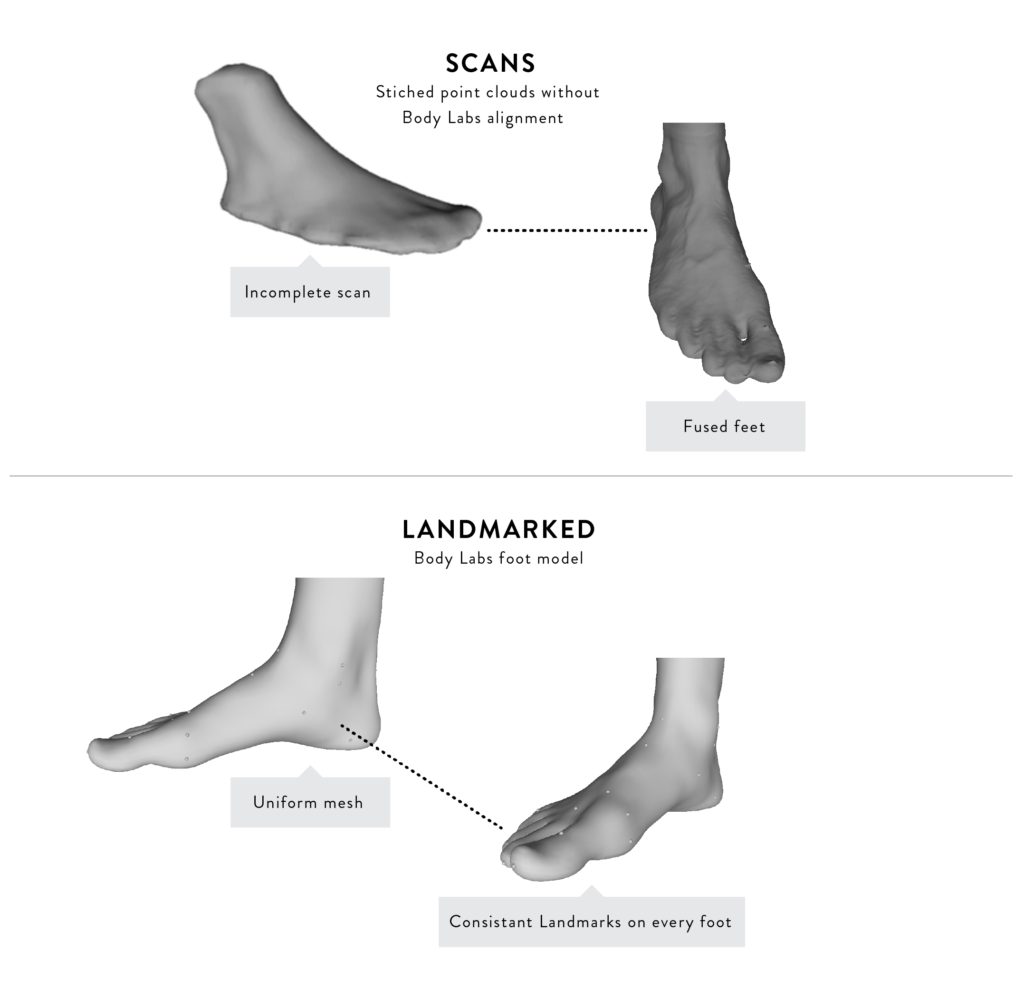

Enter Body Labs. At Body Labs, we are focused on creating 3D digital feet that are precise, consistent and scalable. Using our statistical model, we take foot scans and put them in the same alignment every time. With this capability, we always output the same measurements from the same place. Precision becomes simple and not a challenge to maintain. With this, your custom products can now be designed without distractions and optimized for success. With digital foot models, we can explore design in so many different ways that were never even a part of the design process.

Enter Body Labs. At Body Labs, we are focused on creating 3D digital feet that are precise, consistent and scalable. Using our statistical model, we take foot scans and put them in the same alignment every time. With this capability, we always output the same measurements from the same place. Precision becomes simple and not a challenge to maintain. With this, your custom products can now be designed without distractions and optimized for success. With digital foot models, we can explore design in so many different ways that were never even a part of the design process.

When a person takes a sketch into CAD and creates a model, there is a traditional set of steps they take to create their product. Points are laid out, curves are drawn to connect points, curves are connected together to form a surface and then surfaces are stitched into a solid. With a foot model, we can start with the surface of a foot and manipulate geometry to create a truly custom product. Gone are the ideas of measurements and points. Now, surface modeling can start at the foot and then become something truly synonymous.

If custom design isn’t your solution for feet, there is still so much you can do with a foot model. So many insights can be gathered from a foot model. Just having the ability to compare feet enables someone to see how and where a foot really is changing in geometry and bone alignment. An arch can be defined as an area of variability rather than as a point or a curve. A foot model can also be used to explore what an ideal foot is and looks like.

Ideal foot shape geometry is usually evaluated with a good gait cycle and proper form. When trying to correct someone’s foot or promote a proper cycle, one challenge is seeing how that foot will look throughout their gait. What’s great about Body Labs’ simulation is that if a proper gait cycle is recorded, it can be applied on all other feet thereafter. Someone can easily see how misaligned a foot is throughout its gait and then adjust their product’s design to properly promote the function they desire.

The possibilities are endless. You can simulate a foot pivoting on the basketball court or a foot landing off of a long jump. Finally you can see what the foot will do in specific actions and design for these extreme conditions. Product design is meeting a new digital age that will change how we think through design. Forget about trial and error, with Body Labs your foot is ready to be designed for.